The future of Nuclear Energy in the UK Energy Mix?

- Jan 19, 2018

- 13 min read

This post provides an overview of the current nuclear energy production in place in the UK at this moment with an overview of the proposed nuclear new build plants and their various stages of development. This post gives you a look at the process from start to finish and provide links to videos and other great resources if you wish to get into more detail. This post does not go into any future developments of any of the technologies themselves e.g. SMRs. What we do go into is how nuclear fits into the de-carbonisation commitments of our energy supply in future years.

Contents

Nuclear Power vs Nuclear Energy

Nuclear Power in the UK

The Nuclear Fuel Cycle

Presenting…the Nuclear New Builds (NNB)

Fun Facts about Nuclear Power

The UK Energy Mix – where does/should nuclear fit in?

Section 1. Nuclear Power vs Nuclear Energy

Nuclear Energy occurs in nuclear reactions or radioactive decay. The Nuclear Energy that we talk about when generating Nuclear Power is an exothermic reaction which occurs as part of Nuclear Fission. The Nuclear Energy produced from Nuclear Fission is used to generate electricity which is referred to as Nuclear Power.

Therefore, when we talk about Nuclear Power we are talking about using Nuclear Energy,

which produces heat,

which creates steam,

which drives a turbine,

which powers a generator,

which produces electricity.

Section 2. Nuclear Power in the UK.

Nuclear Power provides around 20% of the current energy generation in the UK via the 15 active reactors operating since the mid 1980’s. All but one of these will be reaching the end of their (extended) life by the end of the next decade. We may be able to get a couple extra years out of these but definitely not another 10 years. For information the last reactor that was only completed in the mid-90’s is Sizewell B which will remain operational until the end of its life predicted to be 2035.

Sizewell B remains the only plant utilising the Westinghouse design Pressurised Water Reactor (PWR) in the UK nuclear fleet. When Sizewell B was originally given the go ahead it was planned and the intention was that this would be the first of a fleet of PWR's. However, through the 1990's following a review of nuclear energy in the UK the option of any further Nuclear New Builds (NNB) was off the table due to continued debates around funding, privatisation and dealing with the radioactive wastes.

The other 14 reactors across 7 sites all utilise the Advance Gas cooled Reactor (AGR) British design which was developed from the UK’s first-generation reactor design the Magnox reactor using the same turbines and electrical generation equipment as a coal fired plant. This type of reactor is amongst the world’s most efficient means of converting the energy of nuclear fission into electricity, as well as being extremely safe. As much a feat of ultimate engineering it was the AGR was however, much like the Concorde, complex to build, difficult to operate and very expensive As such the AGR design was not deemed commercially viable losing ground to the US designed PWRs due to the AGR having considerably higher construction costs due to a larger build with tighter tolerances far outweighing the cost benefits of which will be found during decommissioning.

AGR – Advanced Gas-cooled Reactor Source: www.hknuclear.com

The UK energy demand fluctuates depending upon the time of day, year and weather at the time. Nuclear currently offers a baseload energy provision as it runs continuous 24/7/365 regardless of the time of year and weather conditions. This fact is the most compelling reason and understanding of why nuclear will continue to factor in the UKs energy provision to support the intermittent clean energy sources - wind, solar etc. This needs to be the case if we are serious about getting anywhere near to meeting our carbon commitments.

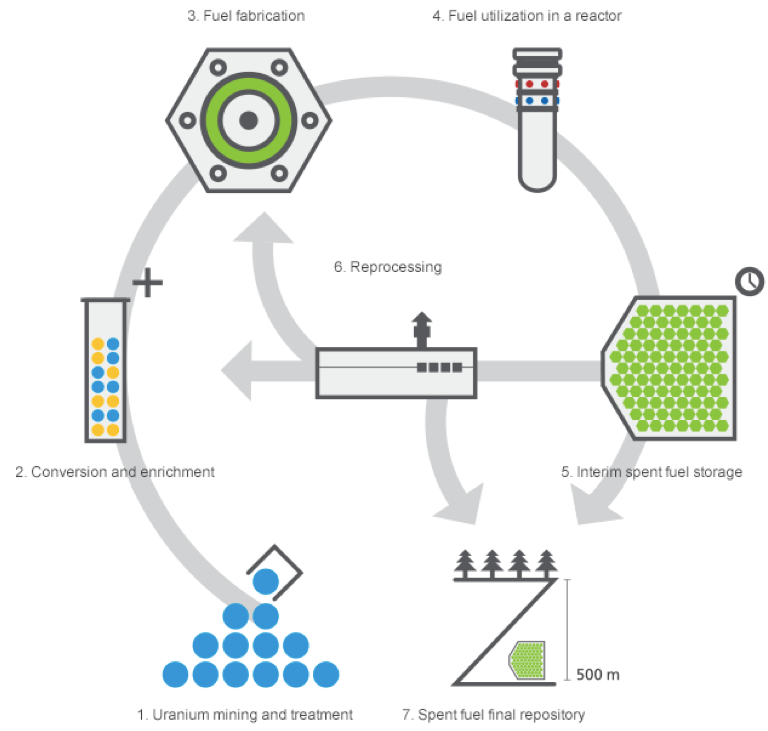

Section 3. The Nuclear Fuel Cycle

The activities required to provide and ultimately dispose of nuclear fuel is what is known as the Nuclear Fuel Cycle. You may be familiar with many of the terms such as mining, milling, enrichment, reprocessing and nuclear waste. What this section aims to do if give you a quick overview of each of the stages of the Uranium Fuel Cycle to give you a broad understanding of the process and the risks, costs and opportunities at each stage.

Nuclear Fuel Cycle

Source: www.seas.sk/nuclear-fuel-cycle

Uranium Mining

Excavation in general will use open pit mining where uranium deposits are close to the surface and underground mining where deposits are deeper. Both of these methods have their challenges and if you are interested you can find out more at ARMS Uranium Holding Co.

In-situ leaching (ISL) is an alternative method which is becoming more and more popular which is where oxygenated groundwater is circulated through a very porous orebody to dissolve the uranium oxide and bring it to the surface which can be recovered from the solution as in a conventional mill.

Uranium Milling

Usually taking place close-by to the uranium mine Uranium Milling entails the extracting of uranium from the mined ore or ISL leachate. Milling includes crushing the ore which is leached in sulphuric acid to separate the uranium from the waste rock. It is then

The milling process results in the production of ‘yellowcake’ which is uranium oxide concentrate usually containing upwards of 80% uranium versus the 0.1% found in uranium ore. Yellowcake is usually stored in 200 litre drums.

Yellowcake in a drum beng ‘handled’

Source: https://www.quora.com/I-would-like-to-study-the-chemistry-of-uranium-as-an-amateur-chemist-and-I-do-not-have-the-facilities-or-the-experience-Is-there-an-element-with-similar-properties-I-could-use-in-my-studies

Uranium Enrichment

Yellowcake cannot be used for fuel as only 0.7% of natural uranium is capable of undergoing fission – the process by which nuclear energy is produced within a reactor (see above YouTube video). The isotope that is fissile in Uranium is U-235, the remainder is the isotope U-238. For fuel to be considered enriched for use in a nuclear power plant (NPP) you need a U-235 concentration of 3.5 to 5%. For information: weapons grade uranium needs to be at over 90% concentration of U-235.

The main process of enrichment uses Centrifuges, the subject of recent contention surrounding the Iran Nuclear Deal. These Centrifuges rapidly spin to separate the gaseous uranium hexafluoride which is converted from the ‘Yellowcake’ Uranium Oxide and is a gas at relatively low temperatures. As the Centrifuges spin the 1% mass differential between the Uranium isotopes allows for them to be separated. This allows for fuel fabrication.

INTERESTING FACT – the US have an alternative nuclear fuel source:

It is interesting to note here that the Russians and the US made a deal in the 90’s in which the weapons grade uranium stockpiled by Russia during 50’s and 60’s is used by the US for nuclear energy production. This diluted uranium constitutes half of the uranium used by the US for nuclear power production. It could be seen as ironic that around 10% of the total electricity produced in the US comes from an energy source that was originally manufactured with a very different intent.

Fuel Fabrication

Most of the reactor fuels that are produced are in pellet form. These are ceramic pellets which are formed by pressing and baking Uranium Oxide. As you can imagine great care is taken when forming the pellets to ensure that they are the exact size and shape required.

Uranium Pellets

The pellets are then encased in metals tubes to form fuel rods which are introduced into a reactor as part of a fuel assembly to start the power generation process.

Generation of power and burn up

To generate nuclear energy to power a PWR you require around 250 such fuel rods from the fuel fabrication process. When introduced to the reactor the presence of a moderator such as water or graphite causes the U-235 isotopes to split and fission generating a lot of heat and causing a chain reaction in the process. This heat is used to generate steam which drives a turbine and ultimately an electric generator. The fuel needs to be removed and replaced one every 12-18 months. This means that around 44 million kilowatts-hour of electricity are produced from tonne of natural uranium compared 20,000 tonnes of black coal or 8.5 million cubic meters of gas.

Used Nuclear Fuel

Once the fuel is deemed no longer practical to be carried on for use in the reactor it is deemed ‘spent’ there is two options; reprocessing or storage and disposal. Used fuel typically has around 1% U-235, 1% Plutonium (around 60% of which is fissionable and can be used in a nuclear bomb), 95% U-238 and 3% is fission products and actinides.

http://nuclearenergyinfo.blogspot.co.uk/2010/10/what-is-spent-fuel.html

Used fuel removed from a reactor emits both a substantial amount of heat and radiation. Most reactor designs have an underwater storage pond close by to the reactor itself which is used to store (with the water providing shielding) and cool (by circulating the same water) the used fuel. It is normal that the fuel will remain in this state for several months before being reprocessed to recycle the useable portion of the fuel or place in long-term storage and final disposal. Remembering that the longer used fuel is stored the easier it is to handle.

Reprocessing

With used fuel containing around 96% of its original Uranium and around 1% Plutonium so it makes sense to recycle as much of this as possible. Reprocessing involves chopping up the fuel rods and then dissolving them in acid. This separates the materials allowing separation of uranium and plutonium into fresh fuel. The remaining 3% of high-level radioactive wastes can be stored in liquid form and subsequently solidified.

Recycling

The Uranium recovered as part of the reprocessing stage can be reused as fuel by following the conversion and enrichments stages again – in fact reprocessed Uranium has a slight higher concentration of U-235 that naturally occurs. It takes about 10-12 reprocessed fuel assemblies to create an enriched uranium fuel assembly.

Source: https://www.jaea.go.jp/english/04/tokai-cycle/02.htm

The Plutonium recovered from the reprocessing stage can be combined with uranium to make mixed oxide (MOX) fuel. Reactors that use MOX fuel substitute U-235 with Plutonium. It take about 8 fuel assemblies to make one MOX fuel assembly.

It is estimated that the reprocessing and recycling of about eight fuel assemblies avoids the need to purchase around 12 tonnes of mined Uranium. There are a couple of new reactor technologies in development which may help to increase this figure.

Wastes

This is probably the most contentious part of any discussion on the use of nuclear energy to provide electricity. Wastes from the nuclear fuel cycle are categorised as high-level, medium-level or low-level.

Low-level wastes are produced during all stage of the fuel cycle

Intermediate-level wastes are produced during the reactor operation and reprocessing

High-level wastes are separated during reprocessing and will contain highly-radioactive fission products and long-lived transuranic elements. This liquid high-level waste is immobilised by being heated to produce a powder which is encased in Pyrex glass, which is poured into a stainless steel canister which can be stored with appropriate shielding.

Small amounts of the depleted uranium can be used in applications such as the production of MOX or can be found in some radiation shielding.

Final Disposal

Overall the wastes associated with the nuclear fuel cycle are of a relatively small volume and there are numerous storage facilities available. The wastes themselves are easier to manage the longer that they are stored. Much of the wastes represent a significant energy source potential energy. All of these factors mean that there is no disposal facility in operation at this moment in time.

The technology of a disposal facility are deemed to be pretty simple. There are a number of studies ongoing but it is expected that the process will involve the placement of the wastes underground before being ultimately permanently sealed.

Section 4. Presenting the Nuclear New Builds

The first of the Nuclear New Builds (NNB) is underway which is Hinkley (not Hinckley!) Point C (HPC) which is under construction which will produce 3.2 gigawatt (GW) of energy. The estimated production demand to replace the ageing nuclear plants is around 18 GW meaning that there will need to be around six HPCs in total. With HPC estimated to cost over £20bn and require an estimated 25,000 workers to complete the works which is forecast to take 7 years. You will be forgiven for thinking if the UK set up to deliver such a large project six-times over?

We, the UK hasn’t built a nuclear power plant for a generation. HPC has now been under construction for around 12 months and there are around 2,000 workers on site on a daily basis. To get to this position has entailed EDF building up a supply chain, although they haven’t started from scratch as there is a large, long-established UK and European nuclear supply chain. Regardless, it is understood that there is far too much work out there for the current nuclear supply chain to handle. EDF along with government, companies and enterprise initiatives have been working hard to bridge the gap. EDF with HPC have the most difficult task as they are the first NNB of a generation and the subsequent NNBs will benefit from the learning from experience (LFE) that will be able to be taken from this project onto future projects – for info; the next plant is Wylfa which will actually utilise a different reactor design.

Work ongoing at Hinkley Point C

http://www.bridgwatermercury.co.uk/news/15588942.New_scheme_to_link_young_people_to_dream_jobs_at_Hinkley_Point_C/#gallery1

One positive for HPC is that it is not the first EPR to be manufactured in the world and by 2019 all of the existing EPRs in construction should be in operation. The first EPR Olkiluoto 3 (Finland) isn’t EDF therefore most of the learning will come from Flamanville 3 (France) and Taishan 1 & 2 (China). One key thing to note here is that although Olkiluto was started first in 2005, Framanville in 2007 and finally Taishan in 2009 it looks likely that they will be completed in the opposite order which shows the learning that has been taken from one to the next - this is obviously massively over simplified and there are numerous reasons for delays on all sites which would form part of a saga length of a post which you don’t want to read and we don’t want to write; but the point is made.

The fact that there is a gap of over 20 years between construction of NNBs has inevitably created the scenario that there is a pool of very skilled, experienced workers who are either in senior positions or are rapidly approaching retirement age and a group of very intelligent, skilled and passionate workers who are very engaged in the industry. The problem is that the UK Nuclear Industry is facing - and in fact the reason for the creation of the get into nuclear website - is the gap in the middle. This is a significant challenge, not insurmountable, but a challenge all the same.

The problem has always been that there hasn’t been the dependable programme of work to maintain such a workforce; even until recently (and ongoing to a certain extent) the media continue to cast doubts over NNBs with HPC and Moorside given in-particular attention regarding whether they will ever be built. Regardless of the upcoming bow-wave of work the UK Nuclear Industry cannot just take the “build it and they will come approach” it needs to get out there, raise its profile and showcase the work and opportunities that are available in abundance.

Something important to add to the discussion is the LEP Network (Local Enterprise Partnerships) are locally-owned partnerships between local authorities and businesses. They play a central role in determining local economic priorities and undertaking activities to drive economic growth and the creation of local jobs. Consider that it is expected that HPC will bring £100m a year to regional economy during peak construction and £40m per year during its 60 year operating life – this too can be expected of the at least 5 additional required construction sites.

This is an important point as most of the proposed plants are in remote areas which can provide much needed opportunity to the local economy. If you are interested you can find an interactive table of the contracts and suppliers here on the EDF Energy Website.

Obviously building up a new supply chain for the non-nuclear work is much less taxing than the nuclear work but initiatives such as Fit4Nuclear are helping to bridge the gap. The industry needs to attract companies (particularly smaller ones) to invest into preparing themselves for nuclear knowing that there is such a significant programme of work on the horizon.

Section 4. Five Fun Facts about Nuclear Energy

To break things up a little and to let the above sink in before we get back into the serious business we’ve listed a couple of fun facts in and surrounding the nuclear industry:

A golf ball size of plutonium weighs in excess of 1kg – just think about it.

Nuclear energy powers the Mars rover.

A USSR spy stole the US nuclear weapons design from the Los Alamos laboratories. These designs were used to develop the first Soviet Union nuclear weapons.

The first nuclear reactor design was a result of the Manhattan Project.

In the event of a nuclear disaster. Removing all of your clothes removes 90% of the radioactive material that you were just exposed to.

Section 5. The UK Energy Mix – where does/should nuclear fit in?

Now let’s get back to business and look at where Nuclear Power needs to fit into the UK Energy Mix going forward. We cannot consider this topic without addressing the elephant in the room… the pricing and financing of HPC and subsequent NNBs.

The strike price for HPC and future projects captures the upfront costs at the start during construction and the costs at the end during decommissioning. This is not necessarily understood or appreciated when reported upon. Additionally, the operator has to put a portion of all revenues to one side for the undertaking of decommissioning and the liabilities remain with the Operator who hold the risk of any additional costs during the decommissioning phase of work. The reason for this is that the more challenging phases for nuclear power production are the start and the end of the life cycle of a Nuclear Power Plant (NPP). The bit in the middle in which energy is produced is for sure the cleanest form of providing carbon free energy to meet the Country’s demand.

This fact isn’t always really considered when reported in the press as decommissioning of the plants is such a long way off and potentially could be 60-70 years down the line. However, it is an important fact as one thing to consider when looking at the costs associated with clean energy is the recent work of the Department for Energy and Climate Change (DECC) and the amount of money (£7.5bn in financial year 2013/14) that they have been needing to spend on an annual basis as a very live example of what costs can be incurred when you do not consider decommissioning in your strike price. The first generation of offshore wind farms are starting to reach the end of their life which have been funded without a provision for decommissioning being considered - hopefully this doesn’t result in the same scenario in the near future.

As we are talking wind and strike prices the recent press coverage of the wind strike price being less than nuclear was in mis-leading to the public as wind is an intermittent energy source and as such cannot provide a caseload energy for the UK with surpluses and deficits in supply on a monthly basis. If wind was to be considered a base-load some type of storage battery would be required which would significantly increase the cost per MW.

The UK Energy Mix

https://www.niauk.org/media-centre/press-releases/nuclear-remains-essential-uks-energy-mix/

At getintonuclear.com we try to keep things as neutral as possible (although we appreciate the bias due to simply knowing more about nuclear than other energy sources). We understand that Nuclear is not the answer to everything but is part of the clean energy mix that is needed if we are serious in meeting our commitments of a decarbonised energy supply.

The first step here is that there needs to be the removal of any animosity that exists between energy sources to truly find the best solution to our problem. There is room in an energy mix for all clean forms of energy - even biomass. This will enable a secure reliable baseload supported by reliable demand management as required.

References and Resources:

http://www.antipope.org/charlie/blog-static/rants/nothing-like-this-will-be-buil.html

https://www-diva.eng.cam.ac.uk/mphil-in-nuclear-energy/external-lectures/2011-12-lectures/edf-energy-ng-cambridge-09022012.pdf

https://atomicinsights.com/water-vs-gas-cooled-reactors-round/

https://en.wikipedia.org/wiki/Nuclear_power

www.hknuclear.com

https://www.seas.sk/nuclear-fuel-cycle

Comments